The Lemico Hydrant Servicer and Hydrant Cart are versatile systems engineered to draw fuel directly from hydrant systems efficiently and safely. Whether you need a truck-mounted module or a compact towable option, we provide solutions tailored to your operation.

Key features of the hydrant servicer include an elevating fueling deck, advanced fuel filtration systems, and intuitive operational components for ease of use and maintenance. The hydrant cart, with its smaller footprint, offers similar performance, ideal for reducing congestion on busy tarmacs while maintaining reliability and safety.

Designed with flexibility in mind, both systems support a wide range of customization options. We can build these solutions on any truck chassis or tailor hydrant carts to meet your specific requirements, ensuring compliance with international aviation standards.

Choose the Lemico Hydrant Servicer or Hydrant Cart for dependable, custom-built refueling solutions that enhance your operations. Contact us to explore your options and get started today!

REFUELING PLATFORMS EQUIPPED WITH ADVANCED FILTRATION SYSTEM

AVAILABLE ON YOUR CHOICE OF TRUCK OR TOW CART

FULLY COMPLIANT WITH EN, NFPA, SAE, EI, JIG, CSA, AND IATA REGULATIONS.

CUSTOMIZABLE TO YOUR SPECIFICATIONS.

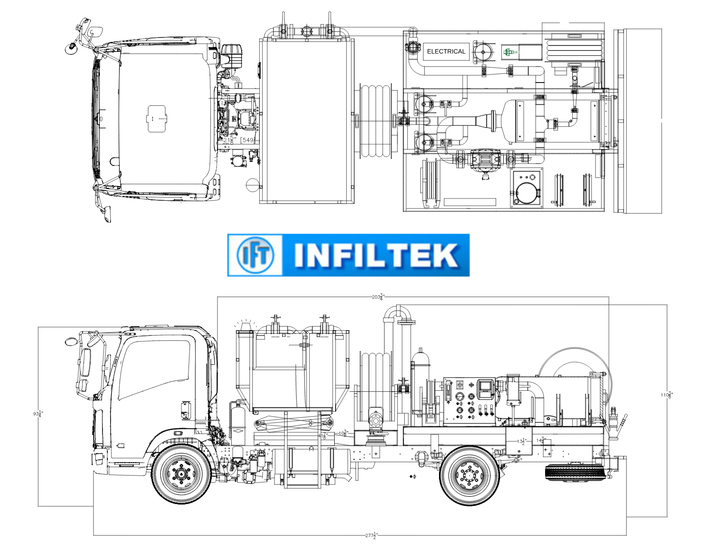

The Lemico Hydrant Dispenser LSHMD-XX-S is a truck-mounted module designed for drawing fuel from hydrant systems. Key features include:

DESIGN:

Elevating fueling deck positioned behind the driver’s cab, with a filter monitor over the rear axle and a transverse hose reel at the rear of the vehicle.

Framework:

Sandblasted and coated steel profiles mounted on the chassis to support the platform and refueling equipment.

Intake Hose:

Swivel-mounted behind the driver’s cab, stowed clockwise and routed around the rear to the operational side. Features adjustable stowage for the intake coupler and trolleys for easy ground positioning.

Operating Components:

Located on an accessible stand on the driver’s side, including meter, shut-off valves, deadman control, sample jar, and gauges.

Pipework:

Stainless steel construction with flanged joints and smooth bends to minimize pressure loss. Aluminum swivels without greasing nipples to reduce maintenance.

Shut-off Valves:

Ball valves for durability and reliability.

Materials:

All components in contact with fuel are made of stainless steel, with internal tin coating for extra protection where necessary.